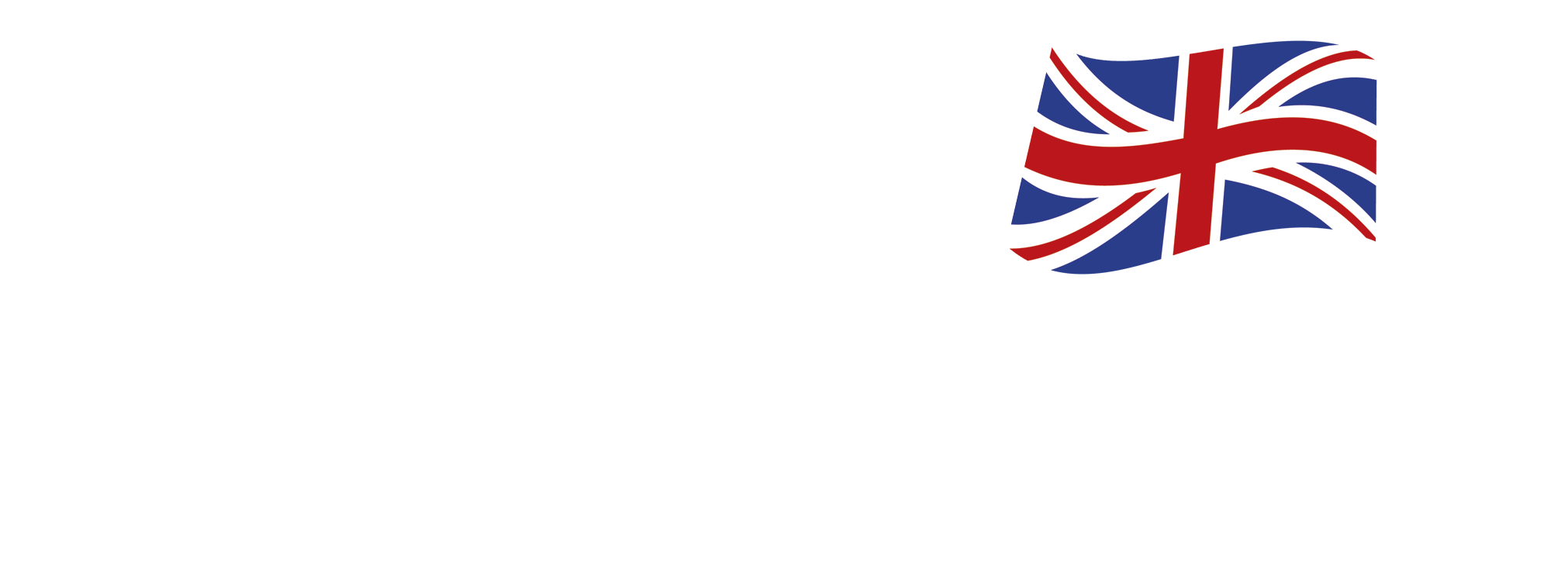

5 & 3 Axis CNC Machining

High-specification, precision engineered parts from materials such as aluminium, steel and titanium or even plastics, polymers & exotics. All produced to fast time-scales. From simple components to highly complex specifications, we select the best machinery to produce your CNC machined parts.

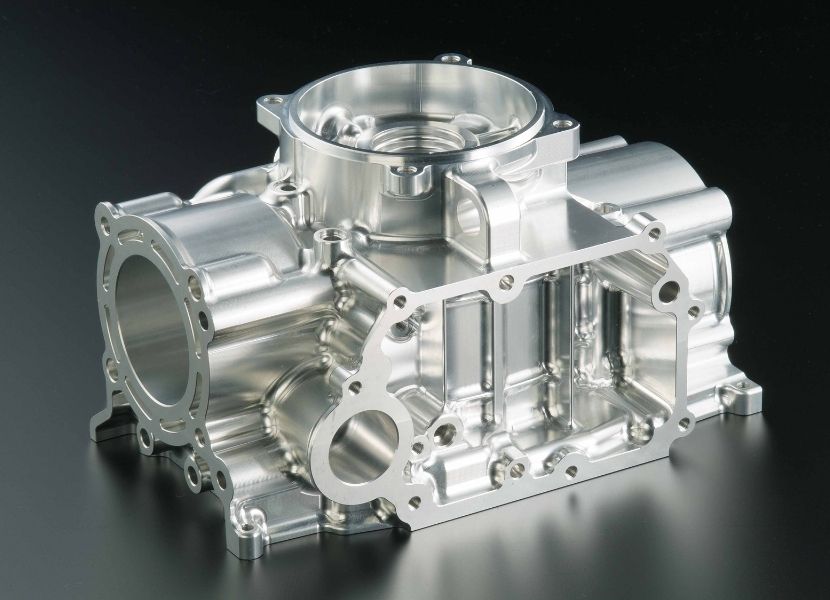

CNC Turning & Mill-Turning

Our CNC turned parts can range from simple rings and shafts to complex curved components. Due to the advanced technology of our CNC machinery we can ensure that your parts fit the specific requirements you need with complete uniformity and perfection. We can deliver high-quality turned & mill-turned parts from a single prototype to hundreds of thousands of parts.

CNC Spark & Wire Eroding

Ideal for working on smaller parts, both CNC spark erosion and CNC wire erosion are perfect for components that have complex/square cornered cavities or might otherwise be too weak for machining. There are no cutting forces so the integrity of the material is always maintained. The process is highly controlled and adds to our precision engineering capabilities even further.

Finishing & Assembly

To complement our production processes, Tml offers a range of additional services that allow products to be fully finished, assembled and kitted according to client specification in-house. Choose from a number of finishing options and feel confident that assembly will be contaminant free.

Quality Test & Inspection

Tml Precision Engineering is accredited by BSi to EN 9100:2018 (technically equivalent to AS9100D and JISQ 9100:2016) and ISO 9001:2015, ensuring that our customers receive the very best precision engineered components through continuous monitoring and rigorous test and inspection.

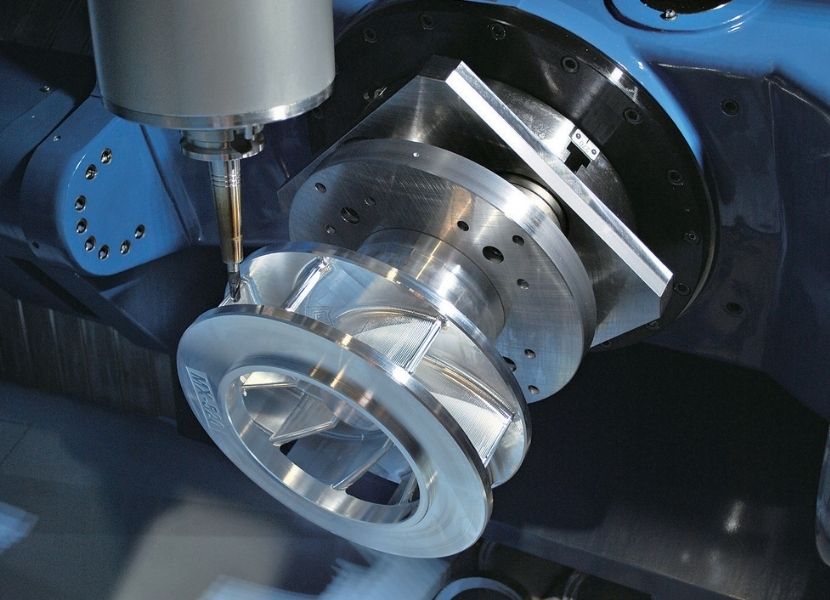

EV Components

The Tml Precision Engineering team provides CNC machining services for a wide range of electric vehicle (EV) component requirements. Our team of experts are well versed in producing the advanced and complex components used in the powertrain and associated requirements.