With our advanced capacity and capabilities, Tml Precision Engineering offers state-of-the-art finished & fully inspected components for some of the leading brands in the world.

High-specification, precision engineered parts from materials such as aluminium, polymers, steel and titanium. All produced to fast time-scales. From simple components to highly complex specifications, we select the best machinery to produce your CNC machined parts.

Prototyping and bespoke production of CNC machined parts. With access to a vast range of state-of-the-art 3-5 axis manufacturing equipment and highly skilled teams, our engineering capabilities have the capacity for any size production run. Each project is meticulously planned and managed from start to finish achieving efficiency, quality and value.

With the latest HyperMill CAM (Computer Aided Manufacturing) software possibilities are endless. Our intelligent off-line programming, data paths trialled, and tool paths perfected in advance of production, we achieve efficiency and accuracy for our customers. From simple components to highly complex specifications, we select the best machinery to produce your CNC machined parts.

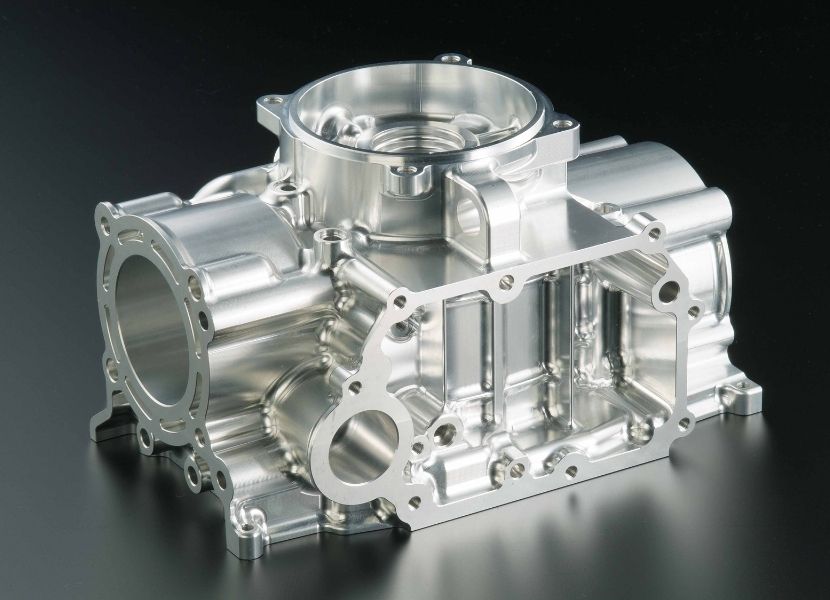

Our CNC milled and/or turned parts can range from simple rings to complex swept surface components. Due to the advanced technology of our CNC machinery we can ensure that your parts fit the specific requirements you need with complete uniformity and perfection. We can deliver high-quality milled/turned parts from a single prototype to hundreds of thousands of parts on time.

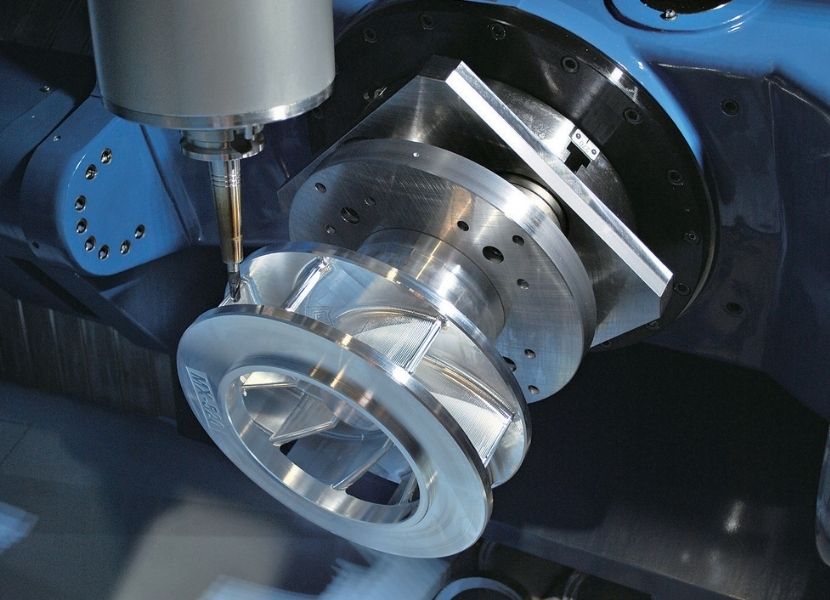

We specialise in 5 axis one hit machining. Tml had multi-pallet unmanned 5 Axis machining capability before any other company in Norfolk. We now have upgraded this to the world class Matsuura machinery. Components can be machined by holding on a single face, permitting the 5 free faces to be machined complete in one operation. This process enables us to leave a wafer thin support wall, the finished component can then be snapped off requiring minimal dressing. Our 5 axis Matsuura machining centres are unparalleled for their production performance, possessing multi pallet changers and hundreds of tools. Coupled with the skill and performance from our team these machines can run for long periods of time reliably and unmanned. The efficiency of these machines is helped with the unique Matsuura I Monitor software, this is used to schedule and monitor work and monitor tool life to ensure the machines are running as efficiently as they can.

Our 9 axis CNC milling and turning machines are the best money can buy. We use these state-of-the-art Mazak Integrex machines to produce high precision components from either solid billets or automatically bar-fed material. All of the operations are carried out in one cycle including the de-burring, therefore creating repeatable high quality components reducing the risk of human error and handling damage associated with multiple operations and finishing manually.

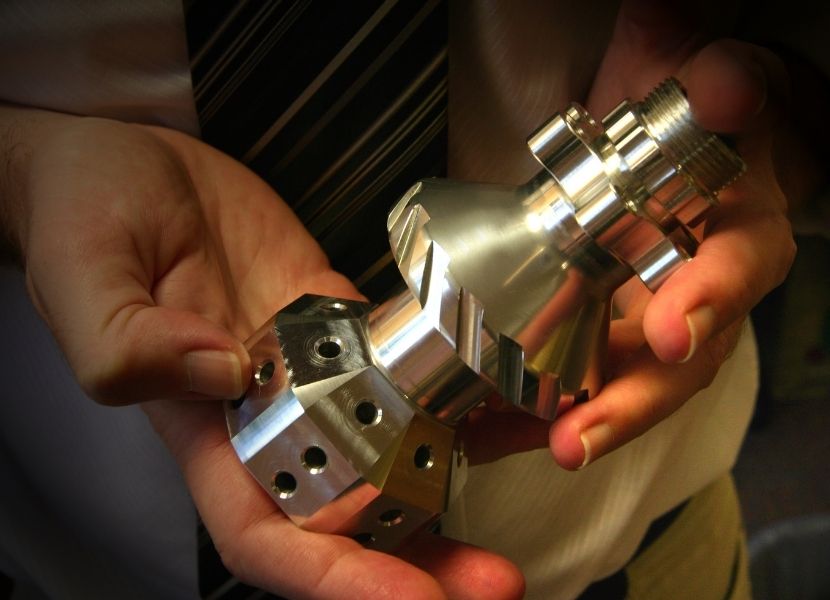

Ideal for working on smaller intricate pieces, EDM (electro discharge machining), also known as CNC spark erosion and CNC wire erosion, are perfect for components that might otherwise be too weak for machining or contain features which can’t be machined using conventional CNC machining processes. Spark and wire eroding can also cut very hard materials that normal machining centres will struggle with.

There are no cutting forces so the integrity of the material is always maintained. The process is highly controlled and adds to our precision engineering capabilities even further.

CNC spark erosion is a great way to machine pieces where the detail required is intricate and complex, such as square holes and pockets with both the equipment and the metal being worked on connected to a current via a custom machined electrode that creates a spark between it and the part whilst submerged in a special insulating oil and thus eroding the material.

Due to increased customer demand we invested in two of the latest Sodick electrical discharge machines (EDM). It gave us the capacity to offer a full service to produce any shape out of a solid, completely removing the need for expensive castings and associated tooling. This makes it possible to produce more low batch complex components including those which were originally designed to be cast.

To complement our production processes, Tml offers a range of additional services that allow products to be fully finished and assembled according to client specification in-house. Choose from a number of finishing options and feel confident that assembly will be contaminant free. Tml can even take care of having instruction leaflets printed and the finish product boxed and bar coded ready to go to into your stock or distribution processes.

Our part finishing processes are second to none and are tailored specifically to our customers’ detailed requirements be they be our specially chosen local sub-contractors or specifically approved or NADCAP certified. Finishing options can include anodising, electro plating, electro polishing, painting, laser engraving, wet and powder painting, explosive/thermal deburring, vibratory deburring, bead blasting and NDT (Non Destructive Testing). More capabilities are available on request.

Cross contamination is completely eradicated through our stringent processes and procedures. Positioned away from the main shopfloor, our in-house assembly department is dirt free and free from risk of FOD (foreign object debris). We carry out inserting and sub-assembly work for many of our customers, including kitting and a full stock management programme. Tml also works with an approved selection of treatment houses for every industry served.

TML Precision Engineering is accredited by BSI to EN 9100:2018 (technically equivalent to AS9100D and JISQ 9100:2016) and ISO 9001:2015, ensuring that our customers receive the very best precision engineered components through continuous monitoring and rigorous test and inspection.

Every component goes through a vigorous inspection process. During its production each component is independently inspected and signed off after each manufacturing operation as well as a detailed final inspection on the completed parts. The inspection is carried out in our temperature controlled inspection department using our huge range of calibrated measuring equipment and gauges including our Mitutoyo and Aberlink CNC CMM’s (co-ordinate measuring machines) with the latest software. Using this software we can measure anything from simple relative positions to full 3 dimensional swept surfaces using CAD comparison to a customer’s model. At the customer’s request we can supply a FAIR (First Article Inspection Report), sample plan inspection reports, CAD comparisons, anything you need to know about your product.

The Tml Precision Engineering team provides CNC machining services for a wide range of electric vehicle (EV) requirements. Our team of experts are well versed in producing the advanced and complex components used in the powertrain and associated requirements. This is a new sector for Tml but is one of great opportunity. We have the skill, capability, and factory resource to deliver any challenge presented to us. Please contact us direct for further information.

Contact our team to find out how our latest advancements in CNC milling and turning; along with our engineering expertise will deliver your parts on time, in budget and quality assured.

World Class. Quality Assured. 24/7 Precision Engineering. National & International Delivery.